If left unprotected, ordinary carbon steel remains susceptible to rust in most environments. For this reason, there are many ways to modify steel to prevent corrosion. Two popular solutions are the use of stainless steel or galvanized steel. While both types of steel protect against rust and corrosion, there are some important differences between them that should be understood.

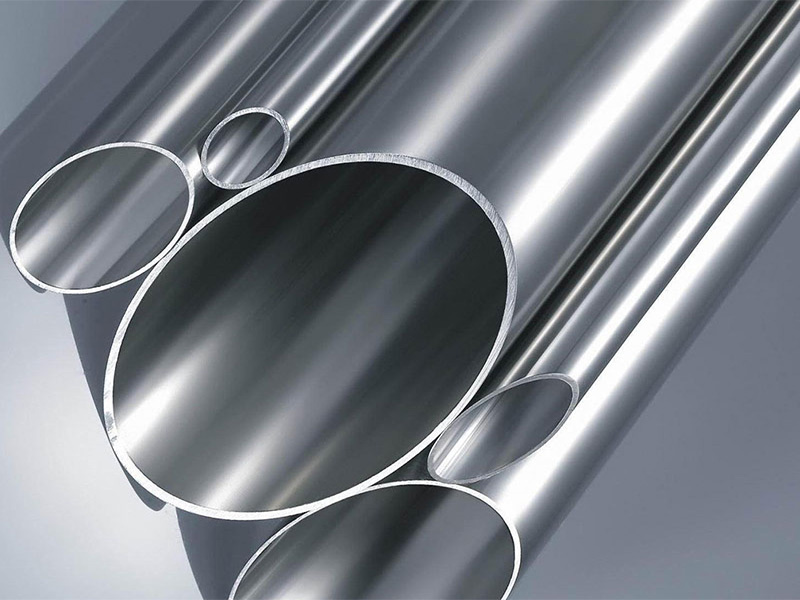

It is resistant to corrosion because of the additional alloying elements in its chemical composition. While ordinary carbon steel is composed primarily of iron and carbon, it has a significant amount of chromium added to help it resist corrosion. Chromium, and sometimes other alloying elements, are added to it during the initial melting process, before it is formed into any particular shape.

Galvanised steel is a type of steel that is coated with a layer of zinc that helps prevent the underlying steel from rusting. The layer is usually very thin, usually measured in thousandths of an inch or micron. To create galvanised steel, the zinc layer is usually added after the steel sheet or plate has been melted, refined and formed. Sometimes it is even applied after a fabrication process (such as bending or welding) has been performed on it.

Galvanised steel resists corrosion because of the zinc coating covering the carbon steel. The zinc layer serves two purposes:

Stainless steel is typically used in applications where the risk of corrosion is high and not permitted. Areas of use for stainless steel include:

Galvanized steel is used in applications where corrosion is not desired, but where a small amount of corrosion may be allowed and there is not much aesthetic impact. Applications for galvanized steel include:

For Further Details,Please Feel Free To Contact Us: